Research projects

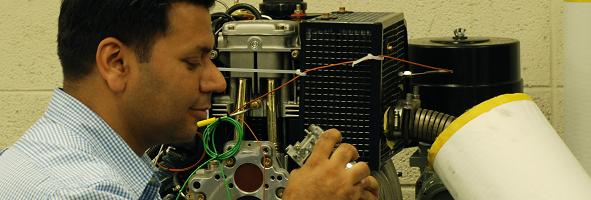

Project: Combustion analysis using ion sensor in single cylinder Diesel Engines project.

Mission: Study of engine performance using io sensors.

Research Facilities:

Engine: HATZ (diesel) engine model no. 1D81, single cylinder

Direct fuel injection, bore/stroke= 100/85mm, displacement= 667cm³, Air cooled

Dyno Engine is coupled with hydraulic dyno for required torque and loads.

Data Acquisition System: Engine Combustion Analyzer by EMA, 8 channel

Fast NOx analyzer (CLD500) from Cambustion for NO detection with respect to crank angle degrees.

Ion Current Amplifier - Omega

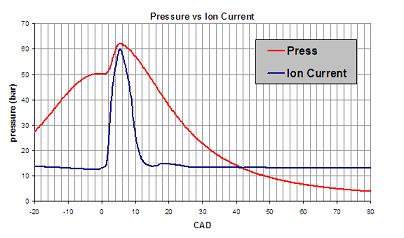

Achievements: A trace showing two peaks of ion current, first one being the higher peak and second a small bump. Comparisons of this trace are being done with NO and cylinder pressure to compare the performance of the sensor.

Researcher:

Jagdeep inder singh

M.S., mechanical (Dr. Henein)

Tel: 313-577-5783

Fax: 313-577-8789

e-mail: ba0935@wayne.edu

Project: Ionization in Diesel Engines

Ion Current is a emerging method of providing feedback to the ECU regarding the process in the combustion chamber and exhaust. The ion current measurement technique helps in acquiring information about start of combustion, pilot injection, NO and various other operating parameters. Compared to cylinder pressure transducers, it is much easier to integrate into glow plug (in Diesel) and Spark plug (in gasoline). It promises great reliability and provides meaningful data for monitoring multiple control variables simultaneously.

Mission: To study the use of university-made ion sensors for detecting NO and combustion analysis at different speed, load and engine timing.

A regular pressure transducer with its amplifier costs around $5,000. For a 4-cylinder engine that accounts to $20,000 and our ion sensors with their amplifiers will cost less than $1,500 for all four cylinders.

Research Facilities:

Engine: Volkswagen 1.9 ltr, 4cyl Diesel Engine

DTS Dyno water brake

ECU ECM by EMA (Electro Mechanical Associates) with ability to control:

- injection timing

- fuel quantity

- up to two injections per cylinder per cycle

- rail pressure

Data Acquisition System: Engine Combustion Analyzer by EMA, 8 channel

Fast NOx analyzer (CLD500) from Cambustion for NO detection with respect to crank angle degrees.

Fuel Metering System from Pierberg

Ion Current Amplifier - National Instruments SC2311 signal conditioning box with voltage amplifying modules

Achievements:

- Use of ion current is far greater than a regular pressure transducer. It can detect combustion quality, NO formation and knock in a gasoline engine. Since the sensors are in-cylinder, the engine can respond much faster and control NO quicker than a regular exhaust sensor.

- Both positive and negative polarities are being used for ion current and their effect is under study.

- Combustion Analyzer 8-channel crank angle based data acquisition system with some pressure traces.

Researcher:

Ashish Gupta

M.S., mechanical (Dr. Henein)

Tel: 313-577-5786

Fax: 313-577-8789

e-mail: ashish5000@wayne.edu

Project: To determine qualitative and quantitative biodiesel emission characteristics.

Research Facilities:

HPLC (High Performance Liquid Chromatography) Waters 600 pump, Waters 2487dual absorbance wavelength detector.

GC (Gas Chromatography) - PerkinElmer ATD 400, PerkinElmer Autosystem GC.

Data collection/analysis - PerkinElmer Totalchrom Software.

Researcher:

Ashley Spears

2007 graduate of Wayne State University, B.S. degree in chemistry.

Project: LTRC-Optical Engine

The Low Temperature Combustion Laboratory is a state-of-the art facility devoted to the research of in-cylinder combustion phenomena. A dynamometer-controlled, instrumented single-cylinder compression-ignition research engine with optical access is uniquely enclosed in a cold room capable of attaining temperatures of -40oC. A battery of diagnostic equipment is applied to study issues related to autoignition, cold-starting, emissions and control. Laser and specialized imaging equipment including spectrometers, intensified ultraviolet and high-speed cameras are used in conjunction with emissions analyzers and data acquisition systems to investigate the combustion process under varied yet controlled conditions. Ongoing studies are directed towards the ‘cool-flame’ phenomena, its effect on autoignition, the ignition delay period and cold starting, and how this process may be controlled to optimize engine performance.

Mission: The Low Temperature Combustion Laboratory is a state-of-the art facility devoted to the research of in-cylinder combustion phenomena.

Research Facilities: A battery of diagnostic equipment is applied to study issues related to autoignition, cold-starting, emissions and control. Laser and specialized imaging equipment including spectrometers, intensified ultraviolet and high-speed cameras are used in conjunction with emissions analyzers and data acquisition systems to investigate the combustion process under varied yet controlled conditions.

Researchers: Radu Florea, Amandeep Singh, Fadi (Dr. J. Marcis)

Project: Transient Engine Testing and Bio-Fuels Emissions Analysis

Mission: For the 2.5L Turbo diesel engine - simulation model (Matlab Simulink) with experimental validation

The 7.2L Mercedes Engine is now instrumented with thermocouples, pressure transducers and ionizations probes for testing bio fuels.

Fourier transform infrared (FT-IR) spectroscopy is a useful solution to the analytical problems of exhaust measurement. Many highly reactive species in the exhaust can be measured by FT-IR down to low part-per-million levels. Analysis of raw diesel exhaust can be made on any engine from the lab.

Research Facilities:

2.5 L Turbo Diesel Engine (VM Motori)

AVL Elin MCA-231 Eddy-current Dynamometer

7.2 L Turbo Diesel Engine (Mercedes)

Test Bed Software PUMA Open V1.2

Data Acquisition system (16 Channels) AVL Indiset Advanced Plus

FTIR Instrument ( Analyzer: Nexus 670 - Thermo, Sampling Station: Rega 7000)

OMNIC Software V7.3

Achievements:

2.5L Turbo Diesel Engine -

- Engine simulation model (Matlab - Simulink)

- Experimental validation (e.g. measured vs. simulated cylinder pressures)

Nexus 670 FTIR Analyzer -

- A single FT-IR may be used to replace 5-6 discrete analyzers. An FT-IR’s response quite stable relative to others analyzers and requires only infrequent recalibration.

- More that 20 species can be analyzed from the diesel exhaust. The behavior of the emissions can be analyzed while the engine switches through different conditions of operation.

Researchers:

Florin Mocanu

Working on: Ph.D.

Wayne State University

Phone: 313-577-5766

Fax: 313-577-8789

e-mail: florinmocanu@wayne.edu

Elena Florea

Working on: Ph.D.

Wayne State University

Phone: 313-577-5766

Fax: 313-577-8789

e-mail: elenaflorea@wayne.edu